Black powder accumulation is a significant problem in gas transmission pipelines. It reduces pipeline capacities, increases costs, and damages expensive downstream equipment.

Here, we look at how oil and gas companies can mitigate the problem of black powder accumulation with the help of an experienced filtration partner.

What is black powder in natural gas transmission pipelines?

Well, just to confuse matters at the very beginning, it's not always black!

The powder is a combination of:

- Accumulated corrosion from the internal surfaces of the pipework

- Erosion of the pipework walls from abrasion from high-velocity hard particulate

- Contamination such as sand/debris that's introduced at the source or during maintenance activities

Depending on the specification of the gas being transported, the fraction of different corrosion products can vary, resulting in a colour variation from black to beige.

Black powder within a natural gas transmission pipeline.

Black powder can be a mixture of any of the following:

- Iron Oxide

- Iron Sulfide

- Metallic iron particles

- Sand

- Clay

- Magnetite

- Mineral scale from produced water (calcium/magnesium carbonate)

Every natural gas transmission pipeline suffers from some degree of black powder accumulation in its lifetime. Routine pigging, maintenance, and the use of internal coatings can all help to reduce the incidence of particle accumulation. But it's impossible to never eliminate it entirely.

Why is black powder accumulation a problem?

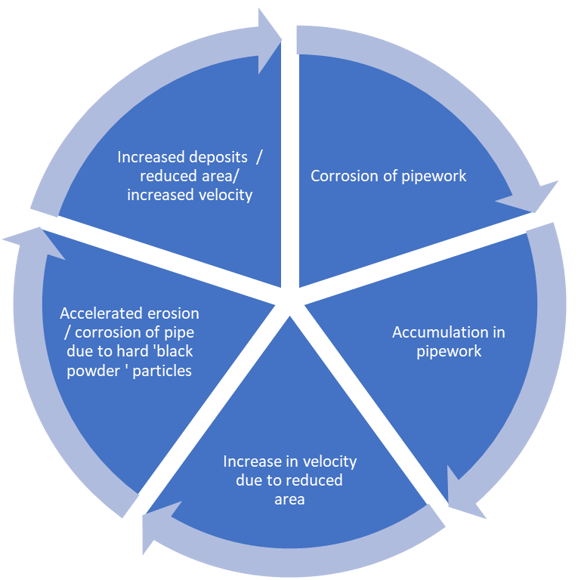

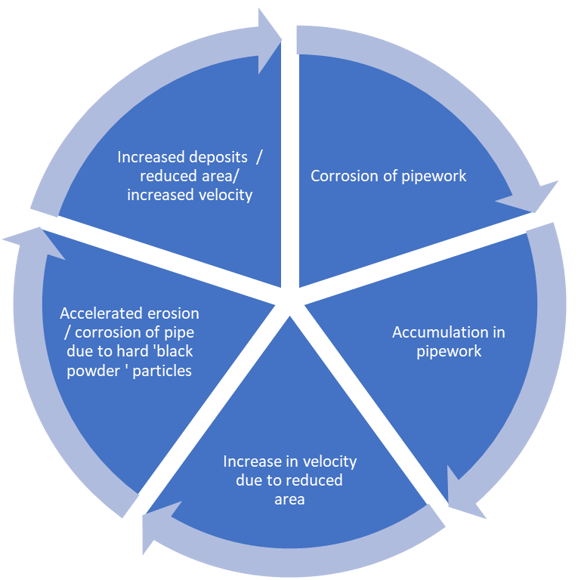

Natural gas eventually ends up in natural gas compressors stations, either reciprocating or turbine. These can be catastrophically damaged by the particulates re-entrained from the floor of the distribution pipe into the gas stream. Unfortunately, this is inevitable as the schematic below shows:

While reciprocating compressors can often cope with particulate around 1 micron, turbine compressors are far more sensitive. These compressors need to be protected by removing the particulate.

Black powder removal from transmission pipelines

An experienced filter manufacturer can help you overcome this problem.

The most common and low-risk method of black powder removal is through dead-end filtration. This provides a guaranteed removal rate independent of gas velocities, unlike separation technologies such as cyclones.

The wide range of particulate sizes present in the gas stream means that designing a filter that both protects the compressor and provides a suitable service life is a big challenge.

Manufacturers of filters for this application often quote efficiencies at 0.3 microns. Is this really that relevant in an application where challenge levels and particulate micron ratings vary so much? At Amazon Filters, we believe there's a better way.

Improving gas transmission pipelines for global oil and gas major

We worked with the specification of a global oil and gas major. This was using the typical particulate loading and micron sizes. This ensured that we not only conformed to their operational requirements but also provided ‘real world’ performance data for use by other potential customers.

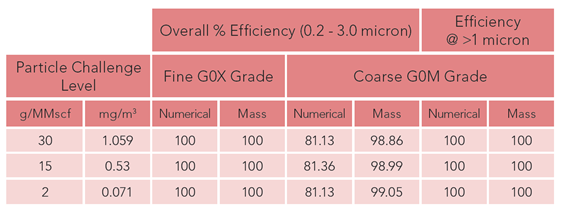

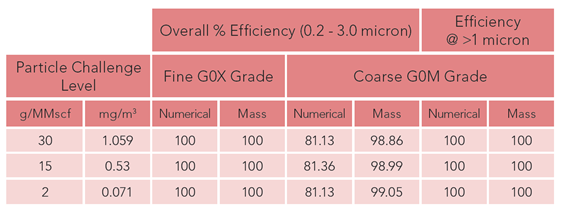

The table below details the efficiency of both the fine and coarse-grade contour gas filter when challenged with three different particle concentrations:

The results show how contour gas provides consistent protection to compressors even in a worst-case scenario of up to 30g/MMscf. To mimic real-world conditions, we measured efficiencies for a particle size range of 0.2 to 3.0 microns, not just 0.3.

The fine G0X grade is ideal for the protection of turbine compressors while the course G0M Grade will provide a cost-effective solution for reciprocating compressors.

Contour gas has been designed with a graded density melt blown structure that optimizes the dirt holding capacity in the more open outer layers while providing a high-efficiency zone downstream to capture sub-micron particulate.

This all assumes that the gas entering the distribution network is conditioned correctly with respect to the removal of liquids.

What else can affect your pipelines?

Health and safety is an extremely important aspect of oil and gas applications. Specifically, the process of cartridge changeout.

When one of the corrosion bi-products, iron sulfide, is exposed to oxygen (as will happen when you open the filter housing) it converts to iron oxide in an exothermic reaction that can result in auto-ignition of the black powder, the filter, or both – as seen in this video:

Working with an experienced filter manufacturer ensures you find the right filtration solution for your requirements. This helps to minimise black powder accumulation which, in turn, helps to improve operator safety and reduce costs.