Demand for sustainable filtration solutions is higher than ever as companies across the process industry look to reduce their carbon footprints. From investing in long-lasting, eco-friendly industrial filters to developing more energy-efficient processes, filtration is a great place to start if you're looking for ways to become more sustainable.

Why put sustainable filtration solutions at the top of your agenda?

Public pressure

Most of us appreciate the extent of the climate crisis. Widespread news coverage of scientists urging governments to act has increased public pressure on companies to improve their green credentials.

Your partners, consumers, and even employees want to know you're doing everything possible to reduce waste and minimise your carbon footprint. For manufacturers, this includes taking positive steps, like installing solar panels on factory roofs, using recycled cardboard packaging, and investing in more eco-friendly filters.

Consumer preferences

Consumers continue to embrace sustainable habits, which extend beyond the individual to encompass companies and their wider supply chains.

68% of consumers say businesses must ensure their suppliers meet high standards of social and environmental practices. In response, many downstream companies will only work with sustainable, eco-friendly manufacturers.

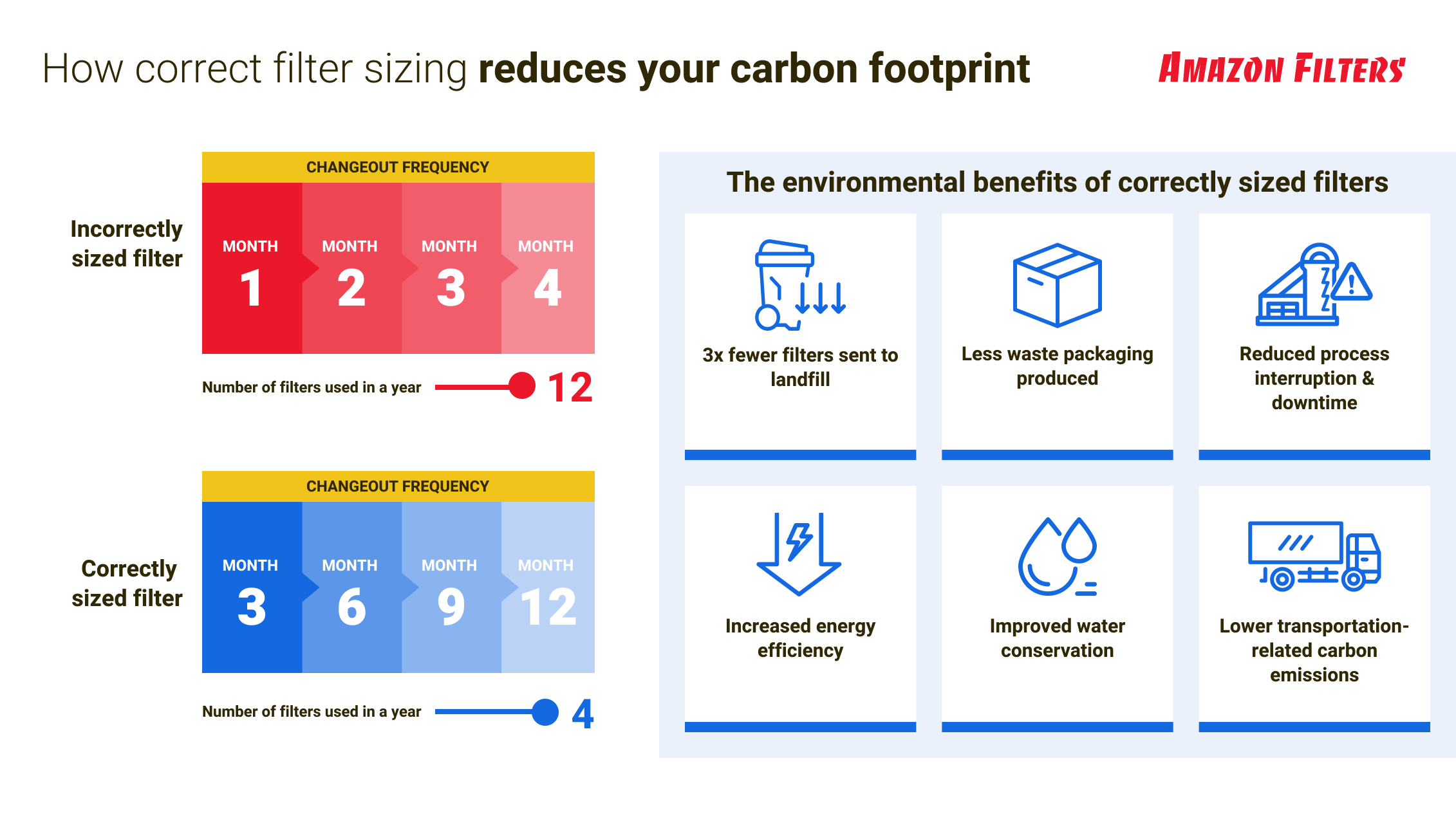

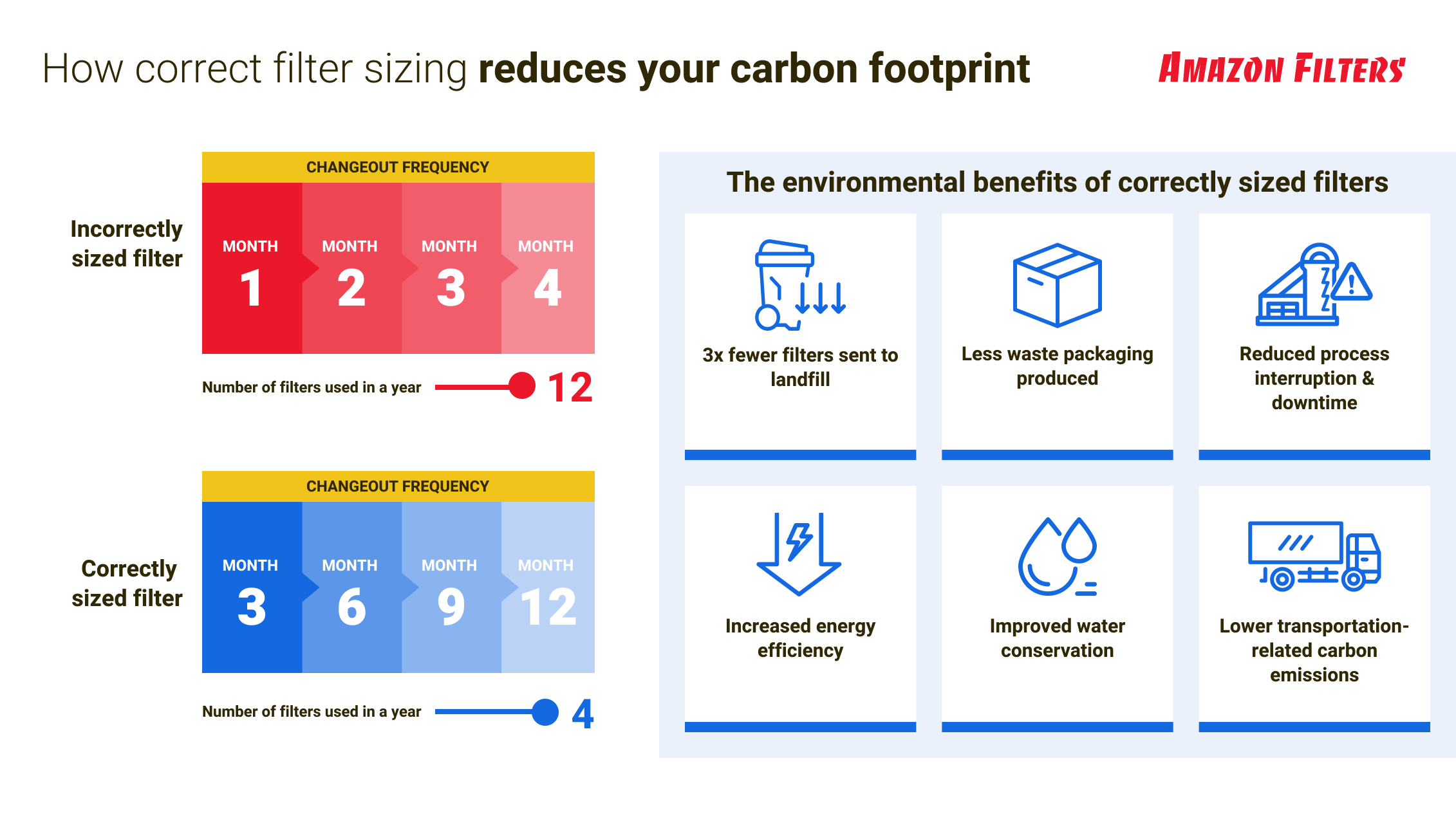

Sustainability is a commitment to making responsible decisions that reduce your impact on the planet. This begins with simple changes, such as investing in longer-lasting, better-fitting filtration solutions. Correctly sizing your filters reduces change-out frequency, which means your processes can run uninterrupted for longer and you produce less waste. It can also lower the total lifetime cost of your filters.

Is it easy to find eco-friendly industrial filters?

When it comes to eco-filtration, sustainability goes beyond the filter itself. Consider the bigger picture. Research your filtration partner's efforts to be greener as a whole rather than assessing a product in isolation.

This is important because if you look at a filter, you might see plastic. Some sustainable filter materials are entering the market, but they're not all compatible with every industrial contaminant e.g., corrosive and hazardous chemicals. In these cases, it's best to talk to your supplier to find a sustainable solution that won't compromise product quality.

Energy efficiency

Sustainable filtration solutions are about more than reducing waste. Equally important are the steps you take to develop more energy-efficient processes.

According to one study, most senior executives and investment professionals will pay a 10% premium to acquire a company with a positive environmental, social, and governance (ESG) record. Similarly, 23% of UK consumers will pay more for goods and services if it helps the provider reduce their carbon footprint.

Consumers also favour brands that embrace circular practices, such as:

- Repair

- Refurbishment

- Reuse

- Recycling

Environmental compliance

Manufacturers must comply with a range of environmental laws, regulations, and standards. These differ from country to country, but the UK alone has hundreds of environmental laws. They cover everything from water quality to habitat protection, and many have a direct impact on filtration systems and processes.

Frequent change-outs and improper handling of hazardous materials can drastically increase your carbon footprint. Working with filter suppliers that use sustainable methods to manage filtration processes, waste, and disposal can minimise your impact on the environment.

Sustainable filter suppliers:

- Have a comprehensive environmental protection policy

- Are ISO 14001:2015 certified

Thought leaders predict that low-carbon manufacturing and industrial systems will stimulate positive change in nearly every industry over the coming years. Manufacturers will design products with sustainability and ethical material sourcing in mind. So, complying with government rules and regulations now will prepare you for the future.

Financial and operational benefits

Companies of every size are embracing sustainability efforts, and nearly all of them have experienced financial and operational benefits.

In one report, 70% of manufacturers said their last environmental improvement helped to reduce costs – mainly by enabling greater efficiency. Operational pressures are also a key driver for adopting more sustainable practices. Many companies say demand from other parts of the supply chain influenced their decision to implement greener processes.

Other drivers of sustainability-focused operational changes include:

- Reputation

- Investor attractiveness

- Backlash against greenwashing

How a filtration manufacturer can support your sustainability initiatives

You don't have to sacrifice quality or efficiency to be greener. The best filter suppliers work with you to provide sustainable filtration solutions that fit seamlessly into your processes. They also identify the small, eco-filtration changes you can make today to be kinder to the planet.

Do more with less

Sustainable filter manufacturers help you minimise waste with quality, long-lasting filters made from eco-friendly materials. When shipping filters, they bundle them together in cardboard or paper packaging to reduce excess plastic.

Streamline your processes

Size matters when it comes to filtration. Suppliers that care about sustainability provide customised solutions that fit your filtration systems and processes perfectly. This minimises downtime and change-out frequency while improving energy efficiency and final product quality. That's the true meaning of eco-friendly industrial filters – filters where the supplier considers sustainability from all angles.

Expert support and advice

Customers are wary of greenwashing. By working with a sustainable filter manufacturer who shares your green values, you get the support to ensure your filtration processes comply with government regulations and meet your corporate ESG requirements.

Protecting our shared future

Sustainable filtration solutions are an investment in our future. Forward-thinking manufacturers that embrace sustainably sourced materials, energy-efficient processes, and circular design principles play a small yet crucial role in preserving the planet's delicate ecological balance.

For more pragmatic manufacturers, sustainable filtration solutions let you run your processes for longer between change-outs. Aside from minimising waste, this increases the total lifetime value of your filters and reduces costs.