Let's get started

We'll make sure you're getting the best out of your filtration system

With glass microfibre-graded density depth pre-filters.

SupaPore VPW

Contract Bottler

UK

Food & Beverage

The increased popularity of low alcohol and alcohol-free beers, combined with the ever-increasing number of independent craft brewers, can cause a real headache for the contractor bottlers of these products.

This shift in drinking habits is especially evident with the younger generation and hence the future market for beers. A recent survey conducted by SIBA (Society of Independent Brewers) in 2020 showed that between 2019 and 2020 the number of young people between the ages of 18-24 years that do not drink alcohol rose from 17 to 23%. It is likely that this trend will continue over the coming years, meaning that the future market will have an ever-growing proportion of low and alcohol free beers. The good news is that the increased sophistication of these beers means the taste is close to that of their alcoholic counterparts. It is even an opportunity to produce unique tastes and product categories.

We worked with a small independent contract bottler to try and overcome the varying filtration throughput achieved on the sterile filling line of these eclectic beers.

One of the production methods for producing low and alcohol-free beers, especially for small craft brewers, is a higher mash temperature. This biological process requires no additional capital equipment whereas techniques such as Reverse Osmosis, Dialysis and Osmotic distillation require a significant investment.

From EBC Brewing Science Group 10th Technical meeting Vienna – September 2014 Marc SCHMITT

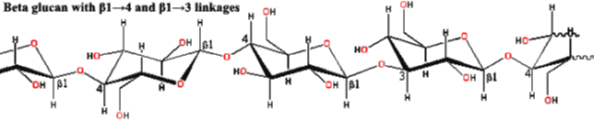

The largest non-starch polysaccharide in barley and malt is Beta Glucan, which constitutes up to 75% of the cell wall, so it is inherent in the brewing process. Typically this is broken down during mashing by the naturally occurring enzyme beta glucanase in the barley. This is also often supplemented by additional beta glucanase additions ). The problem with the higher mash temperature is that this inhibits the activity of the Beta Glucanase reducing the break down of the Beta glucans which then inevitably remains in the brew sent for bottling.

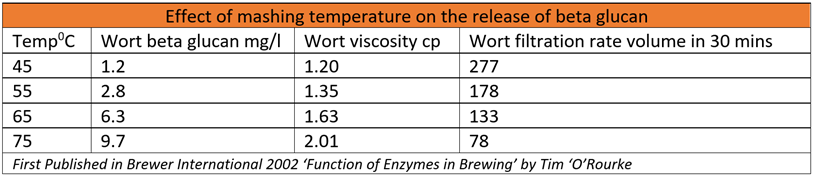

The table below shows the effect of temperature on beta glucan production, wort viscosity and associated difficulty in wort filtration.

Obviously additional beta glucanase could be used to break down beta glucan in the fermentation stages but the fact that bottling is performed at relatively low temperatures (+10 0 C) means that the addition of the enzyme at this stage would have no effect.

The worst case scenario from a filtration point of view is the formation of gels which can very quickly block a typical 0.45 Polyethersulphone (PES) membrane. There have been a number of studies around the formation of the gel form of Beta Glucans which are surmised to be produced by the shearing and straightening of the molecular structure, which encourages gels to form. The customer indicated that it was the gelatinous blocking material observed on the surface of the final 0.45 membranes.

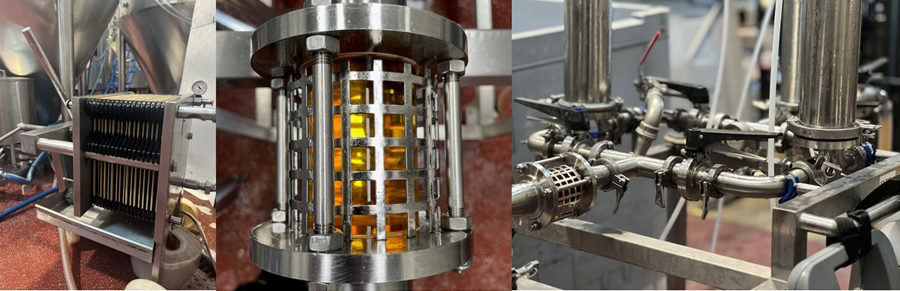

Typical batch volumes were between 850 and 3000 litres. The original filtration set up was through a 3 micron filter press onto a 1.0 micron pleated polypropylene depth filter, then onto the final 0.45 micron PES membrane. This set up resulted in sporadic and rapid blocking of the final membrane dependent on what type of beer was being filtered. A change from 1.0 micron prefiltration to 0.5 micron made no difference to the blockage rates and indeed the prefilters showed no signs of blocking at all. In other words the gelatinous material passed straight through the polypropylene depth filter.

There are a number of possible ways to improve the sterile filtration of the beer:

The 3 micron sheet was not reducing the number of betaglucan gels getting to the final filter, and increasing the efficiency of the cartridge prefilter from 1.0 to 0.5 micron resulted in no improvement.

The switch was then made to a cartridge prefilter using true graded density glass microfibre in place of polypropylene. The prefilter chosen was the SupaPore FPW -X grade which was specifically developed for the protection of our 0.45 SupaPore VP range of membrane filters. The implementation of the SupaPore FPW resulted in at least a doubling of the volume of beer being filtered. The fact that there is such a variation in batch quantity and types of beer (lager, bitter, stouts, low alcohol) bottled at the contractor, along with the pressure of getting product out the door, meant that it was difficult to get definitive scientific data. The result over the last two years is that the customer is using half the amount of membrane filters he once was with no increase in the amount of prefilters used. All while processing an increased volume of beer.

So in conclusion it can be assumed that the use of a glass microfibre graded density depth prefilter in preference to a polypropylene depth filter provides much improved protection to the final 0.45 PES membrane in terms of blockage with beta glucans.

Main Takeaways

We'll make sure you're getting the best out of your filtration system