Let's get started

We'll make sure you're getting the best out of your filtration system

Special OEM product

Global Energy Company

Cooling Water Filtration

Europe

Cost and Supply improvement

Energy

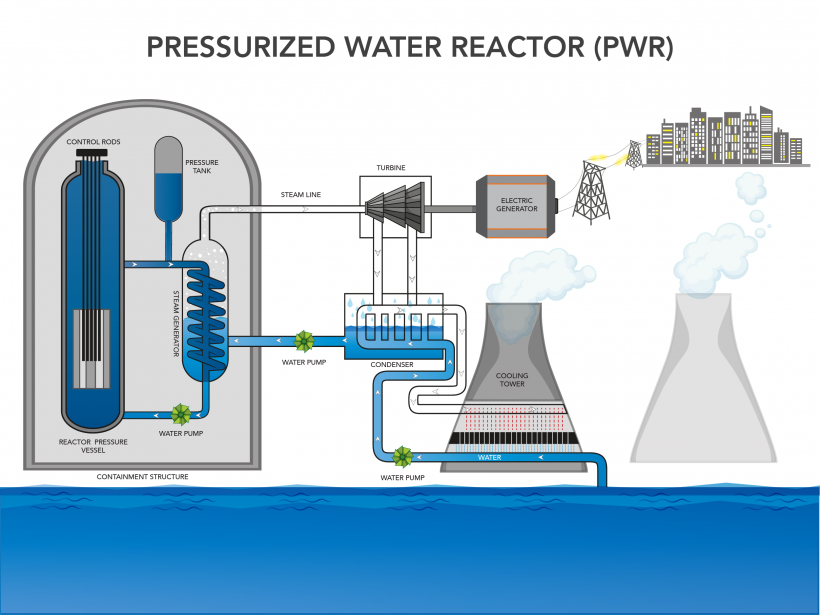

Water plays a crucial role in a Nuclear Power Plant where cooling is critical for safe operation of the facility. This includes water to control the core temperature as well as fuel pool cooling water purification.

Various filtration / purification technologies are used including RO (reverse osmosis) membranes, Iron Exchange resin beds and conventional depth filters.

Water is also utilised as a feed for steam production to power the turbine generators and filters play an important role in condensate polishing.

The Primary Cooling Purification system is responsible for the removal of chemical impurities both soluble and insoluble. Maximising the working life of the purification system before having to replace resins, membranes and depth filters is of paramount importance due to the disposal costs far outweighing the initial purchase cost of the filtration consumable. Extending life also minimises exposure to operators who are tasked with changeouts.

Depth filters can have a profound effect on the lifetime of membranes and resins so the specification and performance is critical.

Amazon Filters were invited to develop a range of depth filters with various micron ratings to be used in PWR (Pressurised Water Reactors) facilities. The opportunity arose due to supply and cost issues with the incumbent supplier.

Amazon Filters were granted Fit4Nuclear status in 2017 by the Nuclear AMRC (Advanced Manufacturing Research Centre) in the UK. This has been followed up recently by Fit4Hydrogen and CCUS (carbon capture and Storage). This provides assurance that we are trusted supplier into the nuclear industry.

The fact that these filters are critical to the safe operation of the nuclear power plant meant that performance testing prior to product approval was extremely rigorous in terms of endurance and efficiency.

Throughout the development process performance was independently verified by a specialist test house.

A range of pleated depth filters were developed based on glass microfibre filter media with micron rating of 1, 5 and 25 micron to accommodate all water applications on site. Parameters tested and validated included

Another simple yet important safety feature of the filter design was the use of colour coded outer sleeves. These relates to the micron rating and ensures that the correct filter specification is always installed for each application. Very simple but very effective.

In tandem with developing a filter that was fit for the customers demanding process, the other prerequisite of obtaining the business was to guarantee supply.

The critical nature of the application means that reliable supply, even in emergency, short lead time requirements, is critical. To this end a dedicated new production cell was established for the assembly of the non-standard endcap design.

If you have an OEM filter requirement or if you are just looking to work with a more reliable filtration partner, why not get in touch today?

We'll make sure you're getting the best out of your filtration system