Prevent contamination and ensure product purity

Whether you need solutions for process water filtration or want to improve the shelf life of your final product, you can rely on our solutions.

Managing filtration to keep the world fed

and safe.

About 4 billion metric tons of food is produced worldwide each year. Aldi, the UK’s favourite supermarket, is supplied with 175 tons of carrots every week alone. Growing, sourcing, manufacturing, packaging, and distributing all this food is no small task. And almost every manufacturing step involves a filter.

From the steam that’s used to clean the bottling production line, to the gas used to sterilise storage tanks of liquids in volume, filters play a critical role in beverage production. Today, 80% of the world’s wine is filtered to some degree.

These unsung heroes keep products clean and free from contaminants like sediments, particles, and bacteria.

They also help to prevent production line problems that lead to product recalls and damaged brand reputations. In December 2021, a Kinder production facility in Belgium detected salmonella in a buttermilk tank. 150 people – mainly children – became unwell and Kinder recalled four product lines. Sales of their products plummeted as a result.

4 billion metric tons = food produced worldwide each year

Products must be high quality to build and keep a loyal customer base. To keep the production line operational and efficient, it’s important to invest in reliable equipment. Operational costs like staff, energy consumption, and equipment repairs also need consideration. Remaining compliant with food production and safety regulations is paramount. And employee safety, well-being, and retention are important, too.

Follow food safety standards.

Standards help ensure that food is safe to eat, meets hygiene and welfare requirements, and descriptions don’t mislead consumers. When unsafe food has left the facility, businesses must withdraw the product from the market and make consumers aware of the problem. Filters remove contaminants from food and drinks, impurities from the air, and sterilise equipment.

|

Regulator: |

Key regulations: |

|

UK regulator: Food Standards Agency (FSA) |

Food Standards Act 1999, Food Safety Act 1990, The Food Safety Order 1991, General Food Law |

|

European regulator: The European food safety authority (EFSA) |

Federal Food Law |

|

US regulator: The Food Safety and Inspection Service (FSIS) and Food and Drug Administration (FDA) |

Federal Food Law |

Optimise performance.

Food manufacturers must create quality products, meet production requirements, and stay profitable. That means operating efficiently and effectively without downtime or product loss. The right filters will result in less downtime, more product production, and better quality.

Enhance the food experience for customers.

Filters reduce the risk of product recalls and improve product quality. For example, water that’s hard or has impurities in it can flatten carbonated drinks. And food production equipment that’s not properly sterilised can grow unwanted bacteria and cause illness. With the right filters, the risk of this happening is much lower. Cleaning the packaging with culinary steam before sealing can keep it free from any unwanted microbes and extend its shelf life. This all adds up to a better experience for customers as they can trust the products to be safe and fresh.

Handling and treating utilities well contributes to smooth and efficient operations. This is especially important in food and beverage production because standards of cleanliness are so high.

All utilities have the potential to cause contamination, so manufacturers need to follow standards relevant to their use. For example, plant steam won’t touch any produce, whereas culinary steam will. That means the steam will have different quality requirements.

Having the best quality utilities for their intended use is a good manufacturing practice. This will prevent problems and safeguard processes. It also means manufacturers won’t need to do as much to the utilities to meet the necessary quality standards.

Example

In the UK, tap water is safe for human consumption so will need minimal treatment depending on retailers’ requirements. In the US, around 10% of the drinking water supply isn’t safe for human consumption. If a facility is in one of these unsafe areas, they’ll need to do a lot more to make the water safe for use in production.

Once you’ve sourced the best quality utilities you can, filters act as a safeguard for your operations.

Filters are integral to the food production process. Here are a few of the ways filters can contribute to a high-quality final product.

Sediment in drinks produces a visible haze, reduces the product’s shelf-life, and makes it less appealing to drink. The clarification and stabilisation processes remove unwanted particles such as sugar, protein, tartrate, and yeast through filters. These processes de-haze the drinks and help to keep them stable. If they’re unstable, they can continue to ferment after bottling and the all-important flavour will change.

Removing unwanted particles through a filter with a reliable, consistent throughput gives drinks a better appearance, longer shelf life, and consistent taste. It’s important to choose a filter with the right micron rating for the drink you’re making and organisms present, as this can vary and mean different filters will work best for the job. Be wary of a one-size-fits-all approach. Otherwise, you could start making a new blend of red wine and find that your filter blocks mid-batch.

Make sure there’s synergy between the prefiltration and filtration stages of your process. Choose a solution that protects prefilter membranes and helps to extend throughputs and minimise costs of more expensive upstream filters.

Some fresh produce gets picked and washed before going to a supermarket. These are the ones sturdy enough to withstand a wash before getting packaged or sold individually e.g., apples and carrots. Manufacturers will also wash and prepare fruits and vegetables for ready-to-eat salad bags or fruit boxes.

Water gets filtered before washing to remove microbial contaminants e.g., listeria and salmonella. Some supermarkets have strict quality requirements to remove cryptosporidium, too. If present in the water supply, this can cause cryptosporidiosis.

Cryptosporidium is a parasite that causes cryptosporidiosis. Cryptosporidiosis causes diarrhoea, stomach cramps, vomiting, and fever. Both the parasite and illness are also known as “Crypto.”

Filtering water also removes microbes and fungal spores, eliminating contaminants that cause food to spoil faster. This is an easy way to extend the shelf life of a product.

Cultured products need strict, efficient, and consistent processes to prevent microflora and phage in the production line. Phages are viruses that destroy the lactic acid needed to make yoghurt and cheese. This slows fermentation and compromises the texture and flavour of the final product.

To maintain product quality, any gas that contacts dairy products in storage tanks must be filtered so it’s sterile. This prevents microbial contamination and spoilage. The sterile gas is used to:

Inject product (e.g., yoghurt) into pots

Purge product if overfilled

Steam is used to:

Increase the shelf life of products like UHT milk

Control the temperature and consistency of a product

Open packaging before filling

Blanch or peel fruits and vegetables

Filters must be able to deal with bulk condensate and be compatible with food and beverage quality standards, e.g., produce culinary-grade steam. Poor quality steam can result in damaged filtration systems, contaminated final product, and incomplete sterilisation due to the build-up of condensate.

A dairy filtration supplier should be able to optimise your current performance and offer guidance on pipework and condensate trap layout for steam filtration, too.

The filter needed depends entirely on what’s produced and the process step, so it’s always a good idea to talk to an expert first. Here are some examples of what can work:

|

Use |

Filter type |

|

Clarification of microbiological stabilisation of wines, beer, bottled water, etc. |

|

|

Prevention of biofilm on filters used to protect membranes in process water systems |

|

|

Removal of contaminants using the |

|

|

Removal of cryptosporidium |

|

|

Venting of storage tanks |

|

|

Production of culinary-grade steam |

All food businesses must have a management plan based on the Hazard Analysis and Critical Control Point (HACCP) principles.

As they’re required by law to produce food that’s safe to eat, a HACCP plan helps manufacturers to identify critical points in their process where there’s a risk to safety. The plan outlines biological, chemical, and physical food safety hazards and precautions to minimise these risks.

1.Identify and list potential hazards

- Conduct a hazard analysis

- Specify control measures

2. Determine Critical Control Points (CCP)

3. Establish critical limits

4. Set up a monitoring system

5. Create a corrective action plan

6. Validate, verify, and review

7. Keep a record

When it comes to filtration as part of your production process, check the

integrity of your filters at each critical control point to ensure they’re capable of delivering against requirements. These apply to:

Storing whisky in charred barrels adds flavour and colour. But small particles of charred wood fall into the whisky during maturation. This needs filtering out before bottling and drinking.

At our customer’s distillery, their large format pleated polypropylene filters were blocking. The blockage issues changed depending on the whisky type and barrels used. This led to extra time spent on changing filters and higher operational costs because of the need for replacement cartridges.

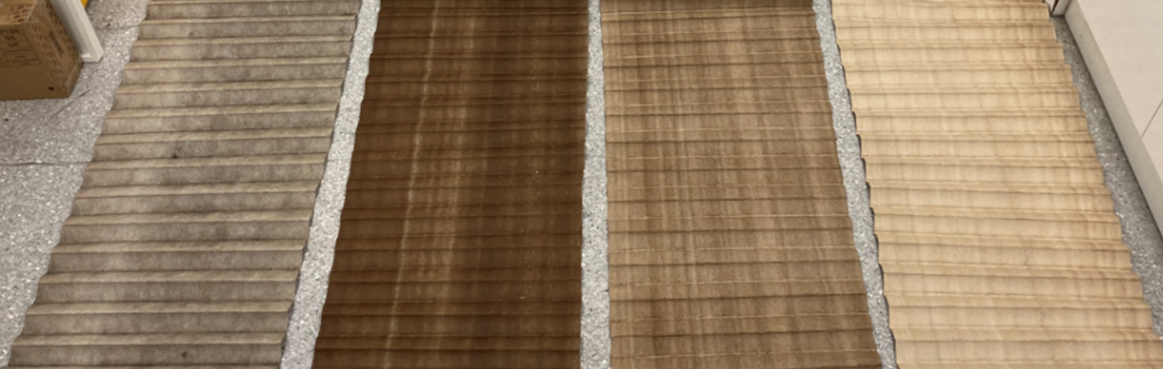

The particulate load on pleated depth filters should be even through the depth of the filtration media. This allows the filters to hold the largest amount of dirt and maintain the flow rate. The filtration efficiency varies through the depth to achieve a balance of filtrate quality and filter lifetime. The efficiency required on each layer depends on the particle size distribution in the fluid filtered.

To understand where blockages were occurring, we examined a used filter and analysed its layers. As the charred wood is easy to see we could locate where the blockages were forming.

The 10-micron filter they were using was mainly removing particulate on the second layer. The upstream layer was too open so wasn’t capturing much particulate. The second layer had too high an efficiency which was causing the filter to block.

We customised our SupaPleat HFC filter with three layers, including a thicker upstream layer. This had the same filtration area as the client’s original solution but with better pleat separation. This is important because if the pleats are too close together it can cause particulate to bridge across the pleats. This means the full surface area of the filtration media isn’t used.

Our solution removed particulate evenly across the layers of the filter, increased the throughput by 20-30%, and maintained flowrate. The filters no longer block prematurely so the client doesn’t have to change filters as often and has a solution that’s better value for money.

Creating a safe, efficient, and cost-effective production facility isn’t easy. Especially against the backdrop of inflation and stringent food safety standards. Having a HACCP plan will help identify and track potential risks, but don’t underestimate the small changes that can have a big impact.

Filters are an integral part of quality assurance in the food and beverage industry, so make sure you have the right solution for your needs. Partner with a filtration supplier who understands your market and processes, can offer expert advice, and will help you get the best ROI.

Today, we’re one of the world’s leading filter manufacturers supported by years of industry knowledge, we deliver high-quality, reliable, and accredited filtration solutions to your exact specifications.

We help you focus on producing high-quality products and services, and worry less about the filtration process.

Competitive, cost-effective pricing

Industry-leading technology

Whether you need solutions for process water filtration or want to improve the shelf life of your final product, you can rely on our solutions.