Let's get started

We'll make sure you're getting the best out of your filtration system

Bespoke housing and SupaPleat Plus

Multi-national supplier of electrolysis plant and equipment

Filtration of Chlor-Alkali electrolyte

Europe

Maintaining efficiency of electrolysers

Green Energy

Hydrogen has been used as a key element for many industrial processes for decades, such as ammonia production for fertilisers, and as a key starter gas for chemical refineries. Today it is also being used as a method of energy storage, which can in turn produce electricity when demand requires, using fuel cells. This is the missing link in providing sustainable renewable energy provision. The hydrogen is used to store the excess energy produced via wind or solar systems so it can be used at times when the sun isn't shining or the wind isn't blowing.

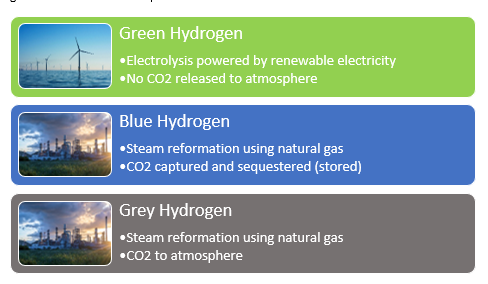

Not all hydrogen production is green, though. Only that which is produced via renewable energy can be termed Green. The table below explains the differences.

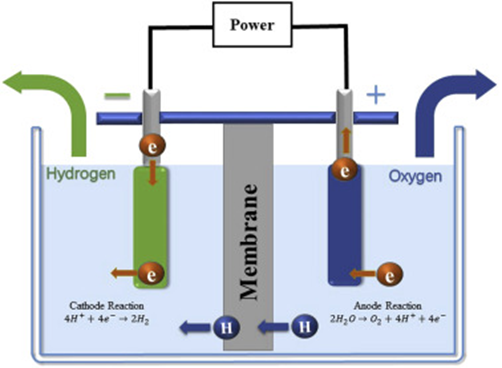

In this case study we will be looking at the production of green hydrogen by splitting water into Hydrogen and Oxygen using the Alkaline Water Electrolysis (AWE) process, powered by renewables (wind and solar).

A typical AWE cell is shown below:

Reliability is key.

For this application of a 20MW modular electolyser based on AWE technology, the filtration of the KOH (potassium hydroxide) based electrolyte is critical to maintaining the highest conversion efficiency.

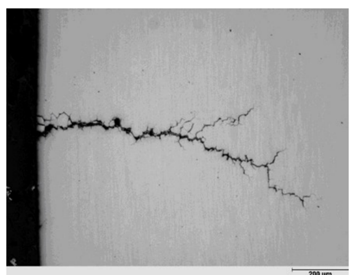

To minimise maintenance costs and maximise in-service life the filter housing design is a critical element, due to the corrosive nature of the electrolyte. The more modern advanced designs of AWE electrolysers are now working at pressures around 3-4 barg and temperatures up to 80 degrees C. This combination, combined with KOH concentrations intermittently up to 50%, and the electrolyte being saturated with hydrogen, means that the use of standard 316 stainless or equivalent is not possible, as it can cause stress corrosion cracking (SCC) as shown:

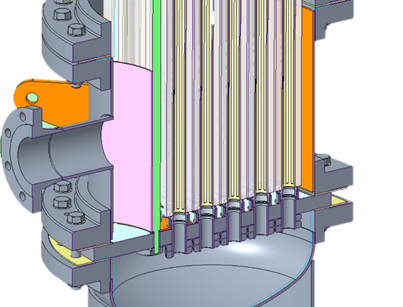

To overcome the chemical compatibility issue, Amazon Filters worked closely with the client to develop an optimised filtration system comprising a filter housing using an ETFE coating on all wetted surfaces. A prototype housing was manufactured and tested by the client to ensure fitness for the process. Unique filter location cups were designed to guarantee the integrity of 'O' ring seals. The tolerance possible on the ETFE coating was not sufficient to guarantee a suitable interference fit for the 'O' ring during all scenarios.

When using coatings of this type it is extremely important to design the components correctly to ensure consistent coating thickness. Sharp edges and complex geometry can often compromise the technical benefits of the coating system. It is important to work with a manufacturer who has practical experience of designing for these types of coatings.

Following successful testing, Amazon Filters are now supplying housings containing 28 * 40" SupaPleat II filter cartridges for each of the 20MW modular electrolysers. The electrolysers have a working lifetime of at least 20 years so the compatibility of the housing and filtrate quality is paramount for trouble-free operation.

Takeaways:

We'll make sure you're getting the best out of your filtration system